This year Kassy and I found ourselves in the greenhouse right about the time when the number of new cases of Corona was increasing exponentially, just before they peaked, and not long after very real meat shortages began. I assumed a constant stream of new cases, and so we did what any dignified gardeners would do: Plant like crazy! We started with Tomatoes and placed nearly 600 seeds in the soil. Next up Peppers with a more conservative 160 seeds, many of which just recently germinated.

After tomatoes, we switched focus to winter squashes. Butternut, Spaghetti squash and Acorn squash have been known to last well into February if stored properly, and so I stopped counting seeds after the sixth tray of Acorn squash.

Kassy planted her traditional center tray full of flowers. At first, I think she assumed that she was losing her normal center tray so that I could grow more food, but I made clear her flowers were a necessity. I just so happened to add a three-tiered shelf right in front to hold more veggies.

Two years ago I received a Aerogarden that allows me to grow cherry tomatoes indoors all year round. This spring I decided to trim the plant and place the trimmings in water to grow new roots. After they had roots I potted them up and placed them in a shaded part of the greenhouse for a few days. Once they were used to the sunlight, I moved them into their current location. You can tell the plants are getting plenty of sunlight as they are compact and not reaching for the sun.

I’m also trying a new method to grow peas. Peas are very easy to grow, but I almost never get any from my garden. Every year it seems one critter or another figures out how to get around the electric fence and eat them all before I can pick them. This year I will not be beaten, and have decided to try this vertical growing method.

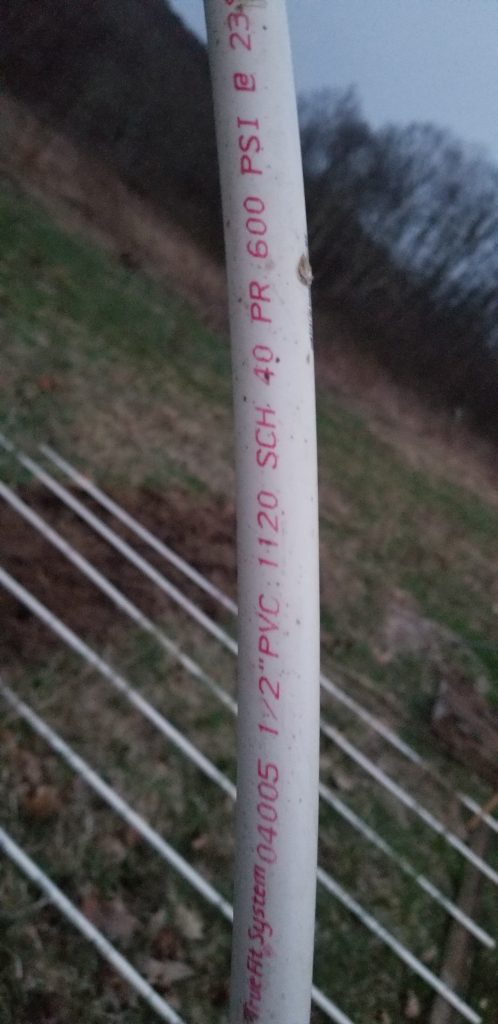

So the idea here is pretty simple, and based on Hydroponics: I have a large tube capped on both ends with holes drilled every inch and filled with water. The holes have small PVC pipe sections filled with soil. My hope is that the roots of the peas will descend into the larger pipe tricking the plant into growing larger then the small pipe would normally allow. You see plants are smart enough to only grow as big above the soil as there roots are below the soil. I’ve tried a very similar setup with lettuce and although it works, the lettuce only grows about 2 inches tall.

My panic has long since subdued, but there has been a noteworthy side effect: 7 gardens have been partially or fully stocked with the plants shown. Now I just need to figure out what to do with the other plants that are leftover… and so I have a new panic, 7 gardens full, and I still have half my plants left. This should be interesting…